Our Support Team has the Answers! From orders to product details, we’re here to help — contact us today!

Day or night, our team is just a chat away.

Get ready fast with step-by-step instructions!

Most orders ready to ship in 1-2 business days.

Extensive warranty available on most products.

Day or night, our team is just a chat away.

Get ready fast with step-by-step instructions!

Most orders ready to ship in 1-2 business days.

Extensive warranty available on most products.

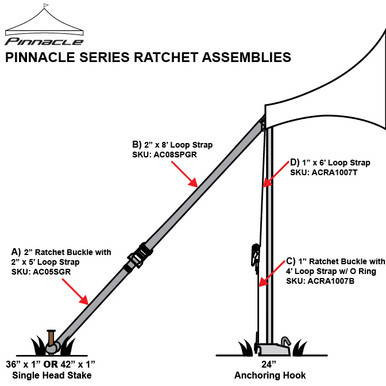

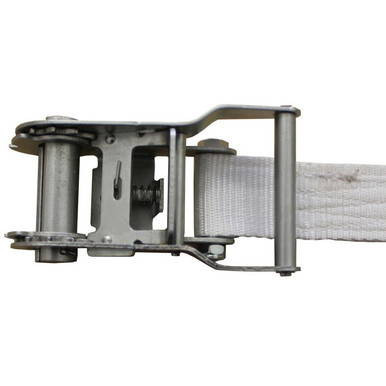

The 1.5'' x 47'' Ratchet Bottom Strap is a compact, high-strength anchoring component designed for secure tent installation. Manufactured using first-run automotive quality seat belt webbing, this strap features a 1.5'' ratchet sewn to one end and an 8'' web loop sewn into the other, providing a reliable and easy-to-use tensioning solution.

This ratchet bottom strap is commonly used in tent anchoring systems where shorter strap lengths are required. Its durable construction and high load rating make it suitable for professional event setups, rental inventories, and cross-brand compatibility.

Proper tensioning is critical to safe and stable tent installations. A ratchet bottom strap allows installers to apply controlled tension to anchoring systems, helping maintain structural integrity during use. This shorter-length strap is ideal for situations where longer ratchet straps are unnecessary or where space constraints require a more compact solution.

Because this strap is designed to be compatible with other tent manufacturers' systems, it offers flexibility for mixed inventories or non-standard setups.

Secure the sewn loop end to the appropriate anchoring point, stake, or hardware as required by the tent system.

Feed the webbing through the ratchet mechanism and begin tightening to apply controlled tension.

Tighten until proper tension is achieved. Inspect the strap and ratchet to ensure secure engagement before use.

The 1.5'' x 47'' Ratchet Bottom Strap provides a durable, compact, and professional solution for tent anchoring applications where precise tensioning and cross-brand compatibility are required.