-

Celina Tent

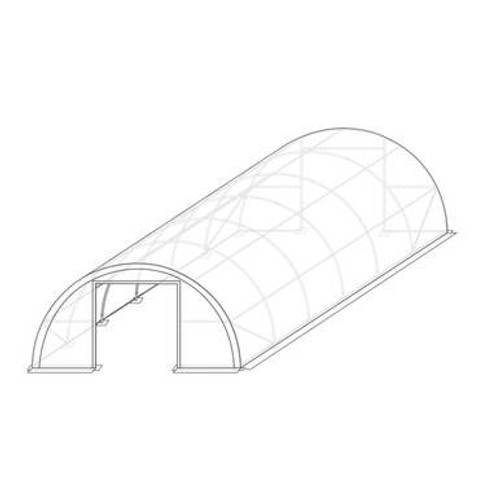

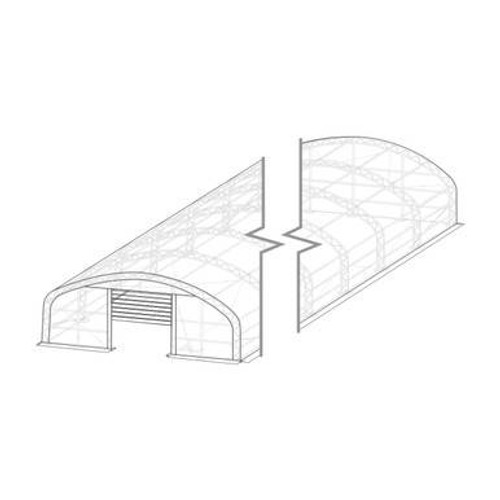

26'W x 20'L x 10'H Crestline Single Truss Arch Container Shelter, Vertical Side

$5,662.18 -

-

-

-

-

Celina Tent

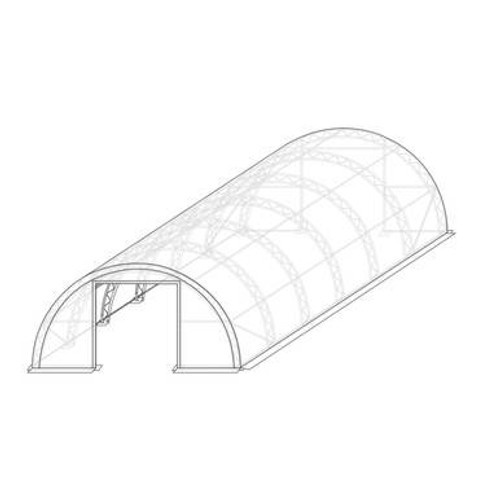

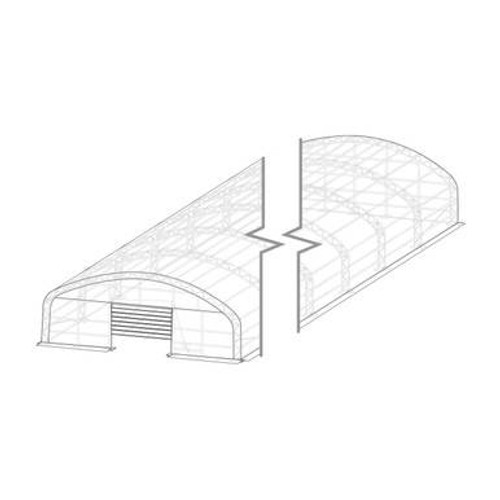

33'W x 40'L x 16'4"H Crestline Single Truss Arch Container Shelter, Arched Side

$10,597.04 -

-

-

Industrial Structures

Solve your space challenges with industrial fabric structures manufactured for the most demanding environments. Whether you need a semi-permanent warehouse or a rugged jobsite shelter, our clearspan buildings provide rapid deployment and long-term durability without the lead times of traditional construction.

key specs

Industrial Fabric Structures for Demanding Operations

Solving Space Constraints Without Construction Delays

Industrial fabric structures bridge the gap between slow, permanent construction and short-term temporary shelters. They provide rapid, reliable space for storage, logistics, and operations when timelines, budgets, or site conditions make traditional buildings impractical.

Clearspan, Steel-Framed Structural Systems

Industrial fabric structures are engineered buildings constructed with rigid steel framing and tensioned architectural fabric. The clearspan design eliminates interior columns, maximizing usable floor space for equipment, vehicles, racking, and material handling.

Built for Long-Term, Industrial Use

Unlike event tents or temporary shelters, these structures are designed for extended deployment in demanding environments. They are engineered to withstand wind, snow, and daily operational wear while maintaining structural integrity and weather protection over time.

Rapid Deployment with Operational Flexibility

Industrial fabric structures can be installed in weeks rather than months, helping operations scale quickly. Their modular design supports expansion, reconfiguration, or relocation as site requirements change—without permanent construction commitments.

key benefits

Why Choose an Industrial Fabric Structure?

Built for Active Job Sites & Daily Operations

Industrial fabric structures are designed to support continuous use by equipment, vehicles, and personnel—holding up to daily operational wear in environments where downtime isn’t an option.

Clearspan Space for Maximum Efficiency

With no interior columns, these structures provide fully usable interior space for storage, material handling, vehicle movement, and racking—helping improve layout efficiency and workflow.

Faster, More Cost-Effective Than Traditional Construction

Get long-term covered space without extended construction timelines. Fabric structures can be deployed quickly with lower total project cost compared to many permanent building projects.

Engineered Durability & All-Weather Protection

Built with heavy-duty steel frames and tensioned architectural fabric, these structures are engineered for wind and snow loads and designed for year-round weather protection when properly specified and installed.

Flexible Layouts, Sizes & Accessories

Customize your structure with door packages, ventilation, insulation, lighting, and anchoring options. Modular designs support expansion, reconfiguration, or relocation as operational needs change.

what's included

Industrial Fabric Structure Systems & Components

CELINA industrial fabric structures are engineered for long-term use in demanding environments. Each structure can be configured as a complete system with the components needed for reliable performance in storage, logistics, and jobsite applications:

Structural Steel Frame System

Heavy-duty steel framing engineered for clearspan interiors and industrial loads, designed to support long-term deployment and daily operational use.

Tensioned Architectural Fabric Membrane

High-strength fabric roof and wall system designed to provide durable weather protection, UV resistance, and long-life performance in outdoor exposure.

Engineered Connection Hardware & Bracing

Industrial-grade fasteners, base connections, and structural bracing designed to maintain rigidity and stability under wind, snow loads, and ongoing use.

Anchoring / Foundation Interface Options

Configured installation solutions based on site conditions—including ground anchoring or foundation interfaces—to support secure placement across varied environments.

Door Packages & Access Solutions

Specify access points for equipment and vehicle traffic, including large openings and door configurations suited to your workflow and material movement needs.

Ventilation & Environmental Control Options

Add ventilation packages to support airflow and temperature management for storage, equipment, and personnel comfort in active operations.

Insulation & Liner Systems (Optional)

Improve thermal performance and condensation control with optional insulation and interior liner packages based on climate and application requirements.

Lighting & Electrical Provisions (Available Separately)

Support extended operations with lighting layouts and electrical routing provisions for safety, visibility, and productivity.

Modular Sizing & Expansion Capabilities

Design for the footprint you need today—with the ability to expand, reconfigure, or relocate as operational requirements change.

choosing the right size

Sizes Available

Choose the right industrial structure size based on equipment access, storage volume, and site constraints. These Crestline configurations are stocked as complete, ready-to-assemble systems with proven footprints for jobsite and warehouse use.

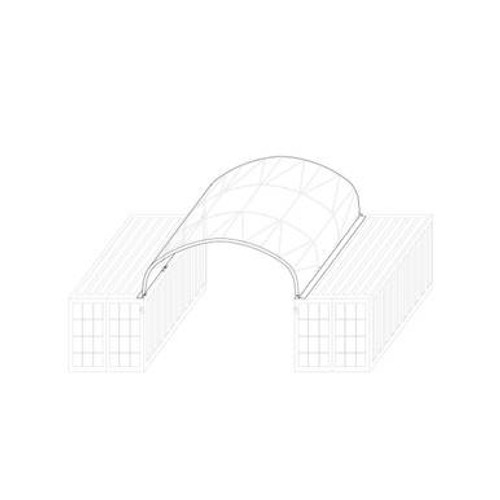

Crestline Container Shelters

26'W x 20'L x 10'H - Designed to create covered storage between shipping containers with a vertical-side profile.

33'W x 40'L x 16'4"H - A larger container-to-container span for increased clearance and usable protected space.

Shop Now

Crestline Single Truss Arch Shelters

30'W x 40'L x 15'H - A compact clearspan shelter for equipment storage, staging, or small operations areas.

30'W x 65'L x 15'H - Extended length for higher storage volume and longer workflow lanes for material handling.

Shop Now

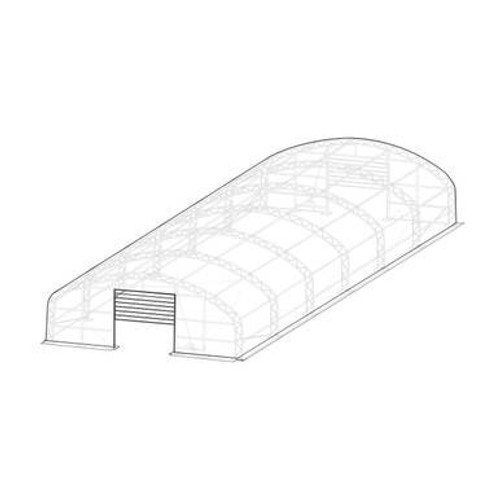

Crestline Double Truss Arch Shelters

30'W x 40'L x 15'H - Double truss strength in a compact footprint for demanding storage and jobsite use.

30'W x 65'L x 15'H - More length for bulk storage, staging, or covered production workflow.

40'W x 60'L x 19'H - Wider clearspan coverage with vertical sides for improved usable interior volume.

40'W x 70'L x 21'H - Increased length and height for equipment, vehicles, and higher stacking/storage needs.

49'W x 115'L x 24'H - Maximum covered footprint for large-scale industrial storage and logistics operations.

Shop Nowstep-by-step guide

How to Select an Industrial Fabric Structure

Industrial fabric structures are not one-size-fits-all. Selecting the right system requires understanding operational demands, site conditions, and long-term requirements. Use the steps below as a starting point—then work directly with our team to finalize specifications.

1. Define the Operational Requirement

Start with how the structure will be used—warehouse storage, logistics staging, equipment storage, maintenance bays, or jobsite operations. Consider vehicle movement, racking systems, clearance heights, and daily workflow inside the structure.

2. Determine Required Clearspan & Height

Select width and height based on equipment size, forklift access, stacking requirements, and vehicle traffic. Clearspan requirements drive structural design and directly impact usability and efficiency.

3. Evaluate Site Conditions Early

Surface type, available space, wind exposure, snow loads, and geographic location all influence structural engineering and anchoring methods. These factors should be addressed upfront—not after a structure is selected.

4. Understand Permitting & Code Requirements

Permitting requirements vary by location, structure size, intended use, and duration of installation. Some applications may require building permits, engineered drawings, or local code review—while others may not. Clarifying permitting early helps avoid delays and ensures compliance.

5. Identify Access, Doors & Workflow Needs

Plan for how equipment, vehicles, and personnel will enter and exit the structure. Door size, placement, and type are critical for operational efficiency and should align with daily use patterns.

6. Consider Environmental & Performance Requirements

Ventilation, insulation, liners, lighting, and condensation control may be required depending on climate and use. These options impact comfort, equipment protection, and long-term performance.

7. Speak with an Industrial Specialist

Industrial fabric structures are engineered systems. Our team will help evaluate permitting considerations, review site conditions, and recommend the correct structure, configuration, and specifications to support safe, compliant, long-term performance.

what sets us apart

Why Buy Industrial Fabric Structures from CELINA?

Industrial operations don’t get second chances. The structure you choose needs to be built correctly, supported long term, and backed by a team that understands real-world operational requirements. Here’s what sets CELINA apart:

✔ Manufacturer-Led Design & Support

CELINA designs and manufactures industrial fabric structures with direct involvement from experienced specialists—not sales reps guessing from a catalog. You get solutions built around site conditions and how your operation functions day to day.

✔ Built for Long-Term, Industrial Use

These are not event tents adapted for industrial work. Our structures are intended for extended deployment, daily equipment use, and demanding environments where durability matters.

✔ Configurations That Match Real Operations

Clearspan widths, wall heights, door packages, ventilation, insulation, and access points are selected around how you move materials, equipment, and people—not generic size charts or off-the-shelf bundles.

✔ Responsive Quotes & Straight Answers

Industrial projects move fast. Our team works quickly to review requirements, confirm feasibility, and deliver accurate pricing—without overpromising or underspecifying.

✔ Long-Term Parts, Service & Expansion Support

We support the full lifecycle of your structure. From replacement components to reconfiguration or expansion, you’re working directly with the manufacturer—not chasing third-party suppliers.

✔ Volume & Repeat-Buy Friendly

From single installations to multi-site rollouts, CELINA supports repeat buyers with consistent specifications, documentation, and streamlined ordering—ideal for contractors, logistics operators, and industrial fleets.

frequently asked questions

Industrial Fabric Structures FAQs

Quick answers to the most common questions about industrial fabric structures, installation requirements, and selecting the right configuration. If you’re unsure, talk with our team—we’ll help you scope the right system for your site and use case.

Do industrial fabric structures require a permit?

Sometimes. Permitting depends on your location, intended use, how long the structure will be installed, and local code enforcement. Before you buy, talk with our team so we can help you understand what your municipality typically requires and what information you may need.

How do I choose the right size?

Start with what must fit inside: equipment, vehicles, pallet racking, material staging, or work zones. Then factor in door clearance, turning radius, and workflow lanes. If you share your use case, our team can recommend the best Crestline configuration for your needs.

What site conditions do I need to consider?

Surface type (dirt, gravel, asphalt, concrete), available space, drainage, wind exposure, and seasonal weather all matter. Anchoring and setup requirements change based on the site—loop our team in early so the structure you select matches your location.

Can forklifts, equipment, or vehicles operate inside?

Yes—these structures are commonly used for equipment and vehicle storage, material handling, and daily operations. The key is selecting the right width, height, and door configuration for your equipment and traffic patterns.

What’s the difference between single truss and double truss?

Double truss configurations provide increased frame rigidity and are commonly selected for heavier-duty applications or larger footprints. If you tell us your use case, site exposure, and expected duration, our team can help you decide which configuration makes the most sense.

Can I install this between shipping containers?

Yes. Container shelters are designed to create covered space between containers for protected storage, staging, or operations. Share your container spacing and desired clearance with our team so we can confirm the right model and fit.

What options are available (doors, ventilation, insulation, lighting)?

Options vary by configuration, but many customers add door packages for equipment access, ventilation for airflow, and lighting provisions for safety and productivity. Tell our team what you’re storing and your climate conditions—we’ll recommend the right add-ons.

Who should I talk to before ordering?

Talk with our team before purchasing—especially if you have permitting questions, challenging site conditions, or equipment/vehicle access requirements. We’ll help you select the right structure, confirm what you need, and avoid surprises during setup.

solve your space problem faster

Get the Right Industrial Structure for Your Site

Industrial fabric structures aren’t a casual purchase. Size, access, site conditions, and intended use all matter—and the fastest way to get it right is to talk with our team. Share what you’re storing, how you’ll use the space, and where it’s going, and we’ll help you select the best Crestline configuration.

Shop available configurations or contact us for sizing, access, and permitting guidance.