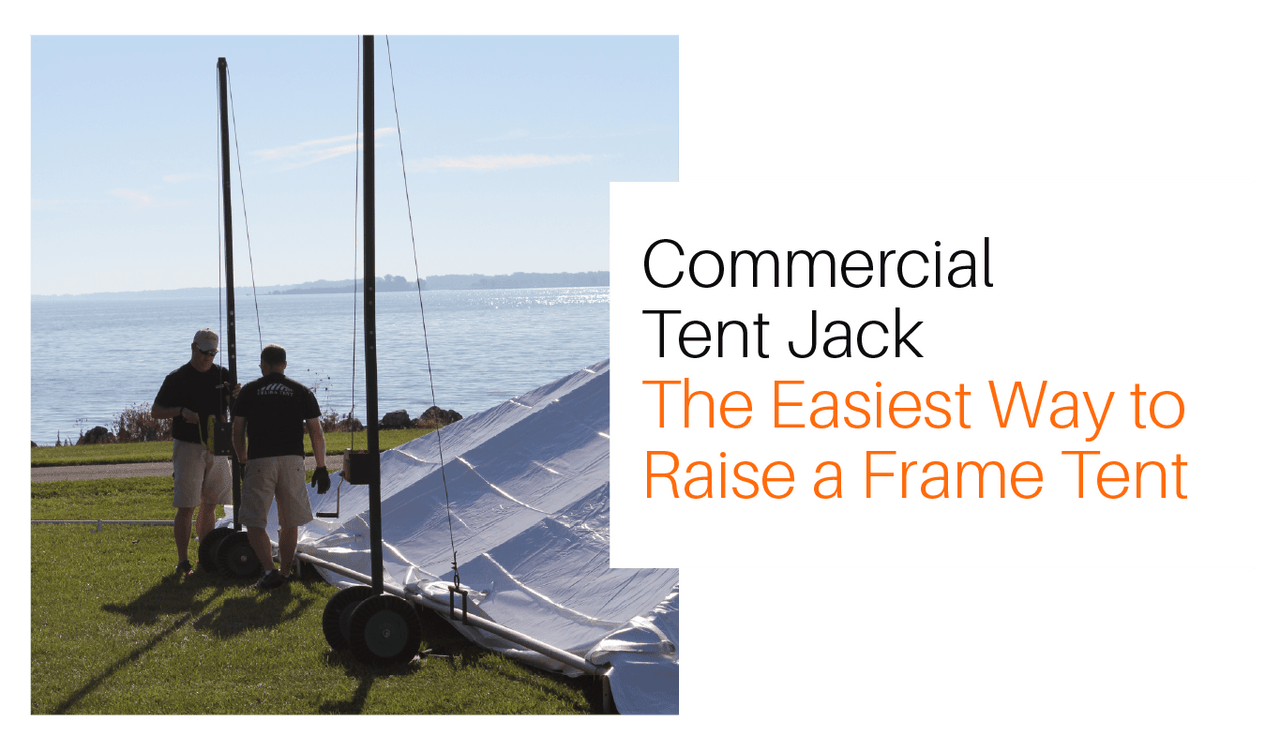

Commercial Tent Jack: The Easiest Way to Raise a Frame Tent

Setting up a frame tent isn’t for the faint of heart. It involves coordinating a team, lifting heavy poles, and often racing against the clock. That’s why every event rental pro or installer should get familiar with one of the most practical tools in the industry - the commercial tent jack.

If you’ve ever wrestled with getting a tent into position, or if your crew has walked away sore and exhausted, it’s time to consider the muscle-saving, time-slashing solution a commercial tent jack brings to the table.

What Is a Commercial Tent Jack?

A commercial tent jack is a heavy-duty mechanical or hydraulic lifting device used to raise the frame of a tent into position during setup. It supports the tent’s weight, reduces manual labor, and makes the process safer and faster—especially for larger tents like 20x30s, 20x40s, 30x60s, or even 40x100s.

Instead of hoisting the tent legs up with ladders or manpower, installers place a tent jack on each corner or side, crank the structure up, and lock the legs in place once elevated.

Key Benefits of Using a Tent Jack for Commercial Setups

Labor Savings

✅ Tent jacks significantly reduce the number of people needed for installation. A job that may have required four to six people can often be done with two or three when you use the proper jacking system.

Injury Prevention

✅ By eliminating heavy lifting and awkward positioning, you help protect your team from strains, sprains, and back injuries. That’s not just good for morale—it’s good for your insurance costs too.

Time Efficiency

✅ Raising a tent manually is slow. Using a commercial tent jack speeds up the job, allowing your team to focus on detail work instead of the grunt work.

Professional Presentation

✅ Tent jacks provide smoother lifts, reducing the chances of dragging or damaging tent legs and fabric. Your gear stays in better shape, and your installs look cleaner.

Types of Tent Jacks

Crank-Style Tent Jacks

- ✅ Manually operated with a turning crank

- ✅ Reliable and cost-effective

- ✅ Great for mid-size tents

Hydraulic Tent Jacks

- ✅ Use hydraulic force to lift larger, heavier frames

- ✅ Minimal effort for the installer

- ✅ Ideal for heavy-duty commercial operations

Dual-Wheel Base Jacks

- ✅ Offer extra stability

- ✅ Prevent tipping or shifting during use

- ✅ Recommended for uneven or soft surfaces

When Should You Use a Commercial Tent Jack?

- Large frame tent setups

- Installations where team size is limited

- Events with tight timelines

- Locations with uneven ground

- Frequent setups where crew fatigue or efficiency is a concern

Even if you only use it for your biggest installs, a commercial tent jack pays for itself in labor and time saved.

How to Use a Tent Jack Safely

- Inspect Your Jack Before Use: Always check for wear, rust, or faulty mechanisms.

- Place It on Stable Ground: Use plywood or level platforms, especially on soft or uneven surfaces.

- Position the Jack Correctly: Center it under the crossbar or lifting point before cranking.

- Lift Evenly: Raise the tent gradually on each corner to avoid stress or bending.

- Lock It In: Once raised, secure all leg pins and reinforcements before removing the jacks.

What to Look for When Buying a Commercial Tent Jack

- Weight Capacity: Match your jack’s capacity to your tent’s size and structure.

- Height Range: Ensure it extends to your tent’s full elevation height.

- Construction: Opt for all-metal builds with reinforced bases for longevity.

- Ease of Use: Smooth cranking or hydraulic operation saves energy and effort.

- Portability: Look for models with wheels or folding components for easy transport.

Why Buy From Celina?

At Celina Enterprises, we offer commercial-grade tent jacks designed for performance and reliability. Our lineup is trusted by event rental professionals, installers, and production teams across the U.S.

“With the right tent jack, setup becomes smoother, faster, and safer—giving your team more time to focus on what matters most.”

— The Celina Team

Make Tent Setup a One-Person Job

Imagine lifting a 30x60 frame tent with just two people—and in half the time it used to take. That’s the power of a commercial tent jack. No more wrestling with steel legs or rushing against the wind. When safety, efficiency, and presentation matter, a tent jack isn’t just helpful—it’s essential.

Ready to streamline your installs and protect your crew? Celina Enterprises has the tools to make every setup smarter, faster, and safer.

FAQ

What size tents can a commercial tent jack lift?

Most commercial tent jacks are designed to handle mid- to large-size frame tents, such as 20x40, 30x60, or 40x100 structures. Always check the manufacturer’s listed weight capacity before use to ensure your jack matches the frame size and material. Celina’s tent jacks are rated for heavy-duty commercial applications and support a wide range of tent sizes safely.

Do I need multiple tent jacks for one installation?

Yes. For even lifting and balanced pressure across the frame, you’ll typically use one tent jack per corner—four in total for a standard rectangular tent. Larger structures may require additional jacks along the perimeter for stability and control during the raise.

Can one person operate a commercial tent jack?

Smaller crank-style jacks can often be handled by a single installer, but for larger tents, it’s best to have at least two people. Working as a team allows one person to crank while the other monitors alignment and safety. Even with a small crew, tent jacks drastically reduce setup time and effort.

What’s the difference between a crank tent jack and a hydraulic tent jack?

Crank tent jacks use a manual gear system for lifting and are ideal for mid-size tents. Hydraulic tent jacks rely on pressurized fluid to raise heavier frames with minimal effort. Hydraulic models are preferred for large, frequent installations where speed and reduced physical strain are priorities.

How do I maintain my tent jack for long-term use?

Inspect your jacks before and after each use for rust, bent components, or worn cables. Keep moving parts lubricated and store them in a dry location. Regular maintenance ensures smooth operation and extends the lifespan of your lifting equipment—especially important for high-frequency rental crews.